Take a behind-the-scenes look at our head design process. Each head we design is 3D printed for analysis and castings are cut to inspect for core shift and thickness. We scrutinize every head to ensure it meets our high standards.

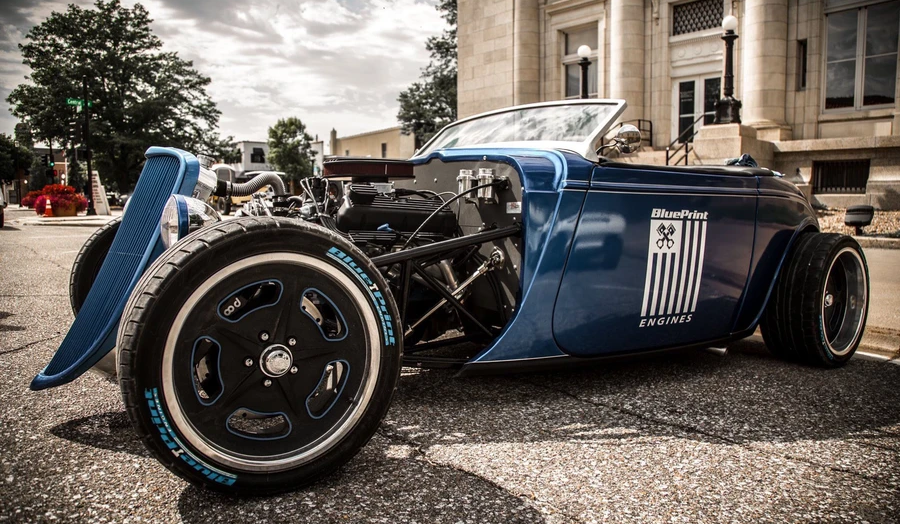

By combining qualified technicians with a passion for performance and by investing in technology, we ensure accuracy and quality in every crate engine we create.

Watch our latest video below to see how it’s done at BluePrint Engines:

With the ability to build up to 75 crate engines a day, there is no shortage of work to be found at the facility. We are always looking to expand our team and have recently added some new jobs on our “Careers” page. Do you enjoy the roaring sound of V8 engines on the dyno? Apply today!