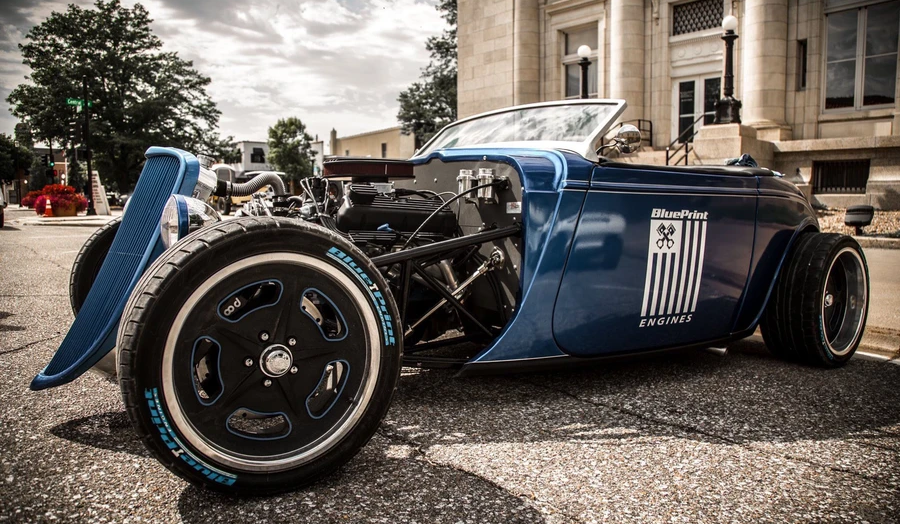

One of the most frequently asked questions we receive at BluePrint Engines is: What parts are used on and go into a BluePrint crate engine?

The short answer: Our own BluePrint designed parts!

With up to 70 crate engines leaving the facility each day – ranging from small blocks and big blocks to fuel-injected LS and stroker engines – many of our suppliers were unable to keep up with our needed quantities. “With our volume and specific applications we are building for, we decided it would be better for us to invest in design and have the parts manufactured specifically to our requirements,” Founder Norris Marshall explains.

Our design engineers will look at what is needed for performance and reliability and design components that meet those requirements. Designing our own components has also allowed us to improve the quality of the parts we use to build our crate engines and ensure all parts are made to our exact specifications. In some cases, it lowers the cost of a component which enables us to pass those savings onto our customers.

Engine parts such as intake manifolds, oil pans, crankshafts, main caps, connecting rods and head bolts to name a few, are first designed as a 3-D model, then printed, tested and revised until BluePrint Engines’ specs and standards are met. We even manufacture our own BluePrint brand engine blocks and cylinder heads!

When you purchase a BluePrint crate engine, you can be assured that each part has been designed and built with quality and durability in mind. We stand by our products and include a 30-month / 50,000-mile warranty with each of our crate engines.

Watch our latest crate engine tech video with Steve Magnante and BluePrint Engines Founder, Norris Marshall, to learn more about how we design our own parts.